The charger manufacturer's production line upgrade.

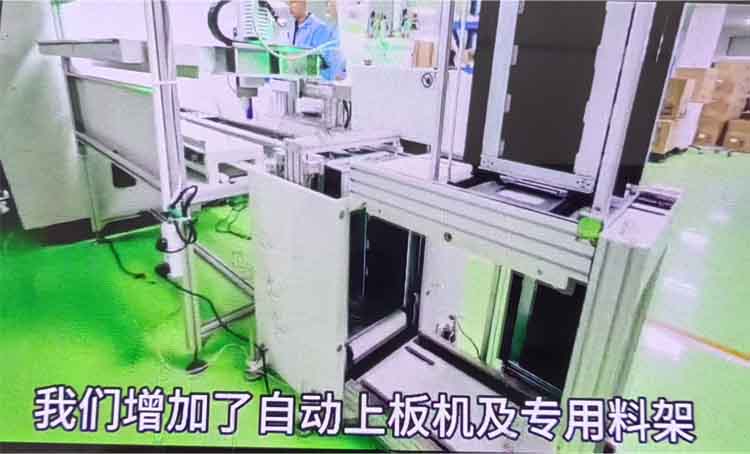

Firstly, there is the automatic board loader and dedicated material rack. This equipment effectively avoids the occurrence of defects such as warping and dropping caused by manual feeding, significantly improving the yield of products after wave soldering. Through the automatic board loader, the production process becomes more stable, reducing human interference and ensuring the accuracy and consistency of product assembly.

Secondly, there is the special-shaped component insertion machine, which features high efficiency and zero misinsertion rate. It can customize various special feeding devices according to the shape of the components, ensuring the correct position and orientation of the components, thereby improving the efficiency and accuracy of product assembly. The precision and reliability of the special-shaped component insertion machine provide strong guarantees for the stability and consistency of the production process.

Wearing static electricity wristbands is essential equipment on our production line. Wearing static electricity wristbands throughout the process effectively eliminates electrostatic damage to electronic components caused by body static electricity, ensuring the quality and stability of the products. The implementation of this measure provides effective protection against damage to products caused by static electricity.

The A01 inspection station before the furnace is an important part of our production process. It conducts comprehensive inspections of products before the furnace online and repairs them by dedicated personnel. By promptly identifying and repairing potential problems with the products, the A01 inspection station greatly improves the yield of products and reduces the rework rate, ensuring the quality and reliability of the products.

Finally, there is the large component dispensing machine. This equipment has precise positioning and accurate dispensing volume, which can firmly adhere components to PCB boards, preventing defects caused by looseness. The use of large component dispensing machines effectively improves the stability and reliability of products, ensuring their safety and durability during use.

In summary, the 2024 upgraded version of Tianyida's production workshop assembly line integrates a series of advanced automation equipment and intelligent technologies. By improving production efficiency, ensuring product quality, and ensuring the safety of the production process, it provides customers with reliable and reassuring products and services. We firmly believe that safety comes from Tianyida, and you deserve to have it.

- Why can lithium batt…

- Chinese electric tw…

- Unlocking the New Er…

- TYD charger safety f…

- The charger manufact…